Are you in the process of a construction project or any kind of building work? Then chances are you have heard terms such as “quantity takeoff” and “bill of quantities,” either through contractors bidding on your job or hearing other people use them. But do you really know how they differ from each other and what their purpose is?

In this blog post, we dive into the details to explain and provide practical advice on when it makes more sense to opt for one over the other. Read on if you want to get up to speed with these two concepts—it might help save some time and money down the line!

Definition of Quantity Take Off

Quantity takeoff is a process used by construction professionals to accurately estimate the scope of work on a given project. It is used to save money and time, as well as reduce waste, by calculating how much material and labor are needed for any project in the pre-construction phase.

They are performed by specialized construction estimators who review plans, sketches, and blueprints of a proposed project and quantify the material and labor that will most likely be required to complete it. It is beneficial because it assists contractors in developing more precise estimates for job bids, which translates into long-term cost savings.

Process for a Quantity Take Off

It is a great tool to accurately estimate the cost and materials of a project. It is a process where measurements are taken from detailed documents such as architectural or engineering plans and specifications.

It can help save time, money, and resources in the long run by having a systematic approach to obtaining and tracking the quantities that are needed for the job. This method also helps with double-checking accuracy measure by measure to ensure that only accurate quantity measurements are taken.

Quantity takeoff necessitates precise measurements as well as knowledge of industry-specific terminology. When you are attempting to take a quantity off, it is important to go through your calculations step-by-step. Doing this allows for easier identification of errors or disputes that may pop up during the project.

It is also useful to have an organized system in place so that you can track parts as you go along. It is a necessary part of any project, and getting it right will ensure smooth operations on-site!

Advantages & Disadvantages of Quantity Take Off

Quantity Take-Off is a great time-saver when it comes to estimating the material needs of a project. It takes the measurements from a drawing and quickly provides a list of necessary materials. This makes it much easier for builders to accurately estimate what materials they need without having to measure everything manually.

While it offers significant advantages, there are also some downsides. If measurements are taken incorrectly or inaccurate information is inputted into the system, any estimates that were based on these incorrect measurements will also be incorrect. To ensure accuracy, double-checking all calculations made by QTO is strongly recommended.

Definition of “Bill of Quantities”

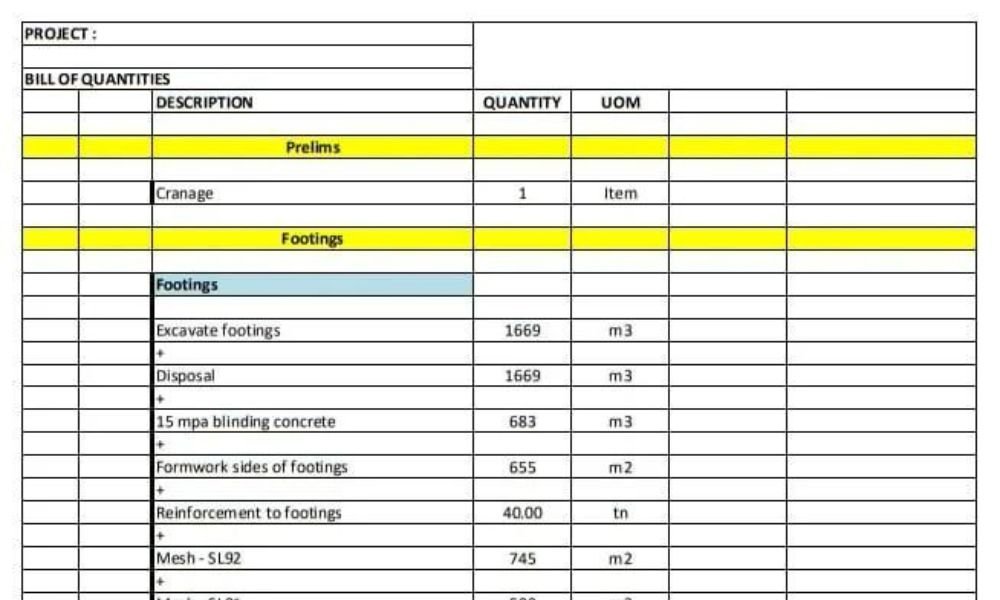

A bill of quantities is a document used in tendering for construction work that provides a complete breakdown of all the materials and components that are required for the project. It lists out the precise quantity and descriptions of materials and labor to be used, as well as their estimated costs.

This document enables accurate pricing to be made and helps ensure that contracts are understood fully by both parties involved in the agreement. It can also track progress accurately throughout each stage of the project, helping to set project timelines and ensure successful completion.

Process for a Bill of Quantities

The bill of quantities is an important document used in the construction industry. It contains an itemized list of labor, materials, and other items necessary to complete a project. Developing a bill of quantities can be a complex process, but it is essential for a successful project that comes in on time and within budget.

It must be reviewed carefully before being approved and signed by both the contractor and the contractor’s representative—two sets of eyes are better than one! Once this step is complete, the bill is ready for implementation.

So make sure to pay close attention when you’re creating your bill of quantities; it is vital to ensuring that your next project goes smoothly!

Advantages & Disadvantages of Bill of Quantities

A bill of quantities is a great tool to use when assessing the advantages and disadvantages of anything. It provides important information about cost, resources, timeline, and potential risks and helps you determine the best overall option for any project.

It can be helpful in evaluating how different solutions would fit your goal while helping weigh the pros and cons properly. Taking the time to draw up an accurate It can really help you make better decisions that will work best for your business in the long run!

Conclusion

The BOQ is a much more detailed way of representing the work required on a project, and as such, it can be quite useful in pre-tender negotiations with potential contractors.

However, the QTO is generally the preferred method for tendering since it provides more transparency to all parties involved. Have you had experience using both methods? Let us know in the comments below which one you prefer and why!

Ready to Simplify Your Construction Estimates?

Understanding the difference between Quantity Take Off (QTO) and the Bill of Quantities (BOQ) is crucial for accurate project estimation and smooth project execution. If you’re looking to streamline your construction estimating process or need expert assistance in preparing precise QTOs or BOQs, we’ve got you covered!

Contact us today to learn more about our professional estimating services. Whether you need help with complex quantity takeoffs, detailed bills of quantities, or guidance on improving your project cost management, we’re here to help.

Don’t let inaccurate estimates slow your project down—get in touch with our team of experts and take control of your project costs with confidence!