In the construction industry, precision and accuracy are the cornerstones of success. Whether you’re a small contractor or managing a large-scale commercial project, having a well-structured Bill of Quantities (BoQ) is essential for ensuring that your project stays on time and within budget.

A Bill of Quantities is more than just a list of materials—it’s the blueprint for effective project management, cost control, and transparency. This guide will walk you through everything you need to know about the BoQ and why it’s a must-have tool for builders.

What is a Bill of Quantities?

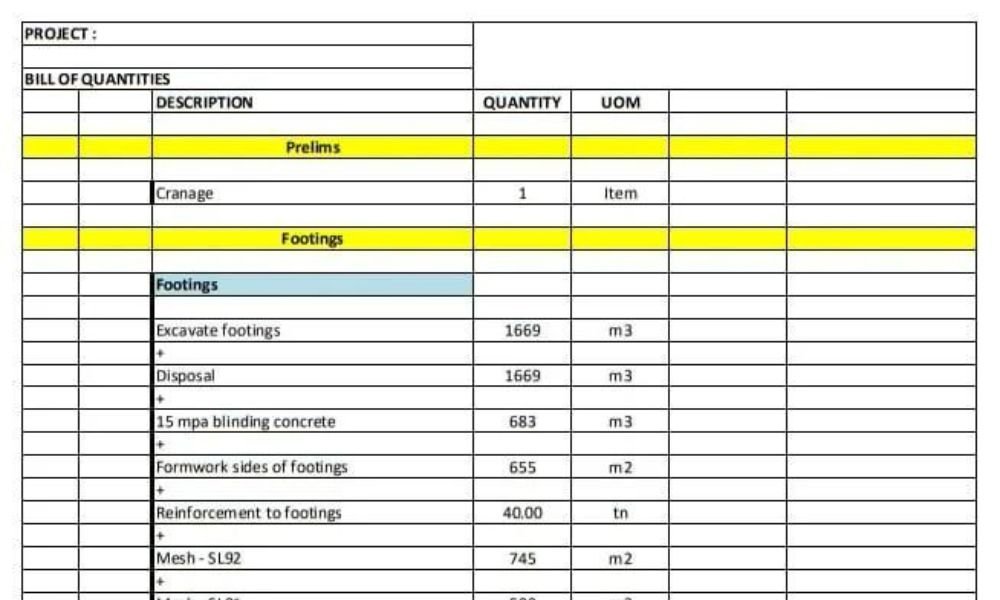

A Bill of Quantities is a detailed document that itemizes all the materials, labor, and services required to complete a construction project. It breaks down each component into measurable quantities, ensuring all stakeholders have a clear understanding of what is needed to complete the job. The BoQ serves as the basis for pricing and tendering in construction projects, giving contractors a transparent, standardized document to base their bids upon.

Why is a Bill of Quantities So Important?

The BoQ is indispensable for contractors, quantity surveyors, and project managers because it provides a clear and precise breakdown of project costs. Here are the key reasons why every builder needs a BoQ:

1. Accurate Cost Estimation

The primary purpose of a BoQ is to offer a detailed list of all the required materials and labor, making it easier to calculate the total cost of the project. By having every component measured and quantified, builders can estimate costs with much greater accuracy, reducing the risk of budget overruns.

2. Fair Tendering Process

A well-prepared BoQ levels the playing field for contractors bidding on a project. Since all bidders use the same document, there is less room for discrepancies or misunderstandings in the bidding process. It ensures that contractors are quoting for the same scope of work, resulting in a fair comparison of bids.

3. Project Transparency

Transparency is key in construction. A detailed BoQ ensures that everyone involved—clients, contractors, and subcontractors—has a clear understanding of the scope of work and the materials required. This clarity reduces the likelihood of disputes or miscommunication during the project.

4. Better Resource Management

The BoQ is an essential tool for managing resources efficiently. It details the quantity of materials and labor required, allowing project managers to ensure the correct amount of resources are ordered and deployed at the right time, minimizing waste and ensuring project timelines are met.

What Does a Bill of Quantities Include?

The structure of a BoQ can vary depending on the complexity of the project, but generally, it will include the following sections:

1. Preliminaries

The preliminaries section covers all the initial groundwork required before construction begins. This might include project details like site clearance, temporary works, safety regulations, and other preparatory work.

2. Measured Works

This is the core section of the BoQ. It provides a breakdown of all the materials and labor required for the project. Each item is listed with quantities measured in appropriate units (e.g., square meters for flooring, cubic meters for concrete). These quantities are typically measured from architectural or engineering drawings.

3. Provisional Sums

Provisional sums are estimates for work or materials that cannot be quantified accurately at the project’s outset. This section of the BoQ allows some flexibility for unforeseen costs that might arise during the course of the project.

4. Dayworks

Dayworks include labor and material costs for tasks that are not easily measurable and are billed by the day or hour. These are often unexpected tasks that fall outside the original project scope but are still necessary for completion.

5. Prime Cost Sums

Prime cost sums refer to the cost of items that are chosen later in the project, such as fixtures, fittings, or specialized equipment. The actual cost is determined at the time of procurement.

How is a Bill of Quantities Prepared?

The preparation of a BoQ is a meticulous process that requires collaboration between architects, engineers, and quantity surveyors. Here’s an outline of the steps involved:

1. Review of Project Documents

The process begins with a thorough review of the project’s plans, specifications, and design documents. This ensures that all elements of the project are accounted for before measurements begin.

2. Measurement

Next, the quantity surveyor will measure the various elements of the construction project. Using specialized software, such as Bluebeam or PlanSwift, these measurements are taken directly from digital plans, ensuring accuracy.

3. Itemization

After measuring, the BoQ is itemized by listing every task, material, and component necessary for the project. Each item is given a description and the corresponding quantity required.

4. Pricing

Once the BoQ is complete, contractors can use it to price the materials and labor. Since all bidders are working from the same document, the pricing process becomes more transparent and competitive.

Types of Bill of Quantities

There are various types of BoQs depending on the project’s size, scope, and complexity:

1. Detailed BoQ

This type of BoQ provides an exhaustive list of every item, material, and quantity needed for the project. It is typically used for large, complex projects where precision is critical.

2. Elemental BoQ

An elemental BoQ breaks the project down into categories or ‘elements’ such as foundations, superstructure, or roofing. It provides a more generalized list of quantities but still allows for accurate cost estimation.

3. Trade Bill

A trade bill focuses on specific trade works such as electrical or plumbing services. It’s often used when different contractors or subcontractors are bidding for specialized parts of a larger project.

Advantages of Using a Bill of Quantities

Using a BoQ provides numerous advantages for contractors and project managers, including:

1. Consistency in Pricing

With a BoQ, every contractor is working from the same set of measurements and specifications. This consistency helps to prevent wildly varying bids and ensures that all quotes are based on the same project requirements.

2. Improved Project Planning

Because the BoQ provides a comprehensive list of all materials and resources required, it is easier to plan for procurement, delivery, and workforce allocation. This leads to a smoother project execution and fewer delays.

3. Reduced Risk of Disputes

Since all costs are clearly outlined in the BoQ, there is less room for misunderstandings or disputes over costs. This clarity helps avoid costly legal battles and improves relations between contractors, clients, and stakeholders.

Common Challenges with Bill of Quantities

While the BoQ is an invaluable tool, there can be some challenges, particularly if the document is not prepared correctly.

1. Incomplete Measurements

If certain aspects of the project are not measured or quantified accurately, the BoQ can become an unreliable guide, leading to underestimating or overestimating costs.

2. Lack of Flexibility

In some cases, the BoQ may not account for unforeseen issues that arise during the project, such as changes in material costs or unexpected delays. While provisional sums can help, it’s important to keep the BoQ updated as the project evolves.

Why Your Construction Project Needs a Bill of Quantities

A well-prepared Bill of Quantities is a vital tool in any construction project. It provides a clear, concise breakdown of all necessary materials, labor, and costs, allowing for more accurate estimates, better resource management, and a smoother project execution. Whether you’re a small contractor or a large firm, the BoQ ensures that your projects run efficiently, transparently, and within budget.

If you’re not using a BoQ yet, now is the time to start. With digital tools like Bluebeam or PlanSwift, creating accurate and detailed Bills of Quantities has never been easier. Start implementing BoQs in your projects and watch your workflow improve, costs decrease, and client satisfaction soar.