When it comes to construction, the accuracy of your estimates is crucial to the success of the project. Estimating the quantity of materials required is one of the first steps in planning, and Quantity Take-Off (QTO) is the process used to determine exactly what materials are needed. Without a precise QTO, your project may face delays, cost overruns, or insufficient supplies.

In this blog, we’ll explore five effective methods for conducting a Quantity Take-Off and explain how each one can be applied to different types of construction projects. By the end of this article, you’ll have a thorough understanding of how to perform a QTO accurately and efficiently, whether you’re working on a small residential build or a large commercial project.

What is Quantity Take-Off?

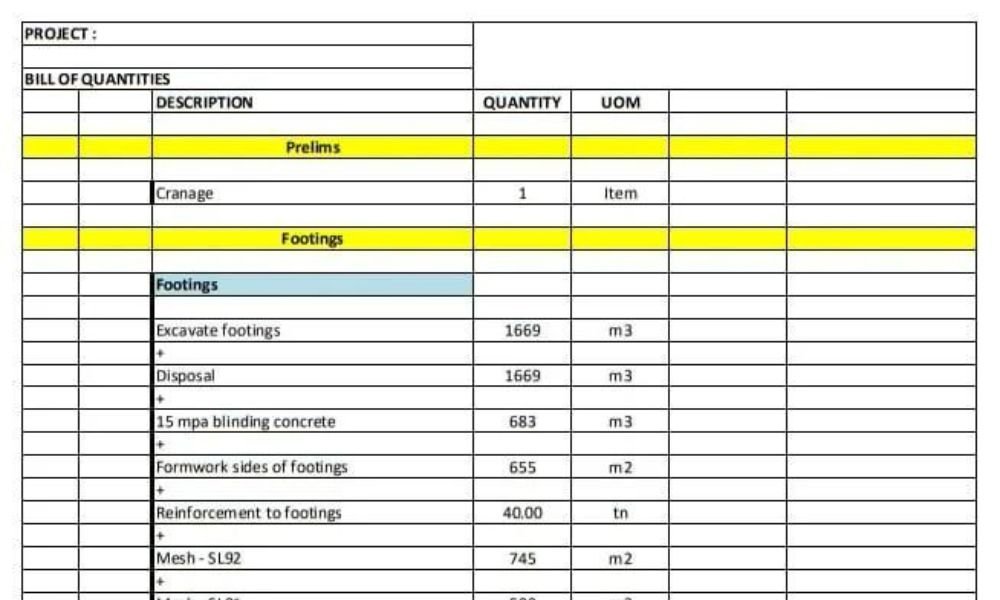

Before diving into the methods, let’s clarify what a Quantity Take-Off (QTO) is. QTO is the process of measuring quantities of materials from construction drawings and documents. It helps contractors determine how much of each material is required to complete a project, such as concrete, steel, or insulation. The QTO serves as the foundation for estimating the cost of the project, ordering materials, and planning logistics.

QTOs are typically performed by quantity surveyors, estimators, or project managers. The information collected during the QTO is essential for project budgeting and procurement. An accurate QTO helps reduce waste, prevent shortages, and keep the project within budget.

Why is Quantity Take-Off Important?

The importance of QTO cannot be overstated in the construction industry. Here are a few reasons why it’s such a critical step:

Cost Estimation: The QTO forms the basis of the project’s cost estimate, which impacts everything from budgeting to contract negotiations.

Project Planning: By understanding the quantities of materials needed, project managers can schedule material deliveries and resource allocation more effectively.

Minimizing Waste: A precise QTO ensures that only the required materials are ordered, reducing excess and minimizing waste.

Avoiding Shortages: If materials are under-ordered, it can result in delays and increased costs, as additional materials might need to be ordered last-minute at a higher cost.

Now that you understand the importance of QTO, let’s explore the five key methods for performing it.

Manual Quantity Take-Off

The manual method is the traditional approach to Quantity Take-Off. In this method, the estimator manually measures the dimensions from architectural and engineering drawings. The materials are then calculated based on these measurements. Estimators typically use rulers, scales, and calculators to perform manual QTOs.

How It Works:

- Review the construction drawings, including floor plans, elevations, sections, and details.

- Identify the materials required for each component of the structure.

- Measure the dimensions of each component (e.g., length, width, height).

- Calculate the quantities of materials based on these dimensions.

Pros:

- Cost-effective: No need for specialized software.

- Customizable: Allows for high levels of detail and adjustments based on specific project needs.

Cons:

- Time-consuming: Manual QTO can be slow, especially for larger projects.

- Prone to Error: Human error can lead to inaccurate measurements or miscalculations.

Best For:

Manual QTO is best suited for small to medium-sized projects where the drawings are not overly complex. It’s also a good option for companies that don’t have access to digital tools.

2D Digital Take-Off

A 2D digital take-off involves using software to measure quantities directly from digital versions of the construction drawings. This method is a more modern alternative to manual QTO and offers increased speed and accuracy. Estimators can import PDF or CAD files into the software, and the software tools allow them to click and measure dimensions electronically.

How It Works:

- Import digital drawings (PDFs, CAD files) into the take-off software.

- Use the software’s measurement tools to click and calculate quantities.

- Organize and categorize materials based on the measured quantities.

Pros:

- Faster than manual methods: The software automates many of the processes.

- More accurate: Reduces the likelihood of human error.

- Easy revisions: If the drawings change, adjustments are easy to make within the software.

Cons:

- Software costs: There is an upfront investment in the software.

- Learning curve: Users need to be trained to use the software effectively.

Best For:

This method is ideal for medium to large-scale projects, where the complexity of the drawings makes manual take-offs too slow. It’s also well-suited for projects where design revisions are common.

3D Model-Based Take-Off (BIM)

A 3D model-based take-off uses Building Information Modeling (BIM) software to extract quantities from a 3D model of the project. In BIM, all elements of the structure (e.g., walls, beams, windows) are created as objects with specific attributes. This allows the software to automatically calculate the quantities of materials needed for each component.

How It Works:

- Create or import a 3D model of the project in BIM software.

- The software extracts the quantities of materials based on the attributes of the 3D objects.

- Generate reports that list the materials and quantities required.

Pros:

- Highly accurate: 3D models provide an exact representation of the project.

- Automated: The software calculates quantities automatically, saving time.

- Comprehensive: Includes not just materials, but other project elements like time and cost.

Cons:

- Expensive: BIM software can be costly, and creating 3D models takes time.

- Requires expertise: BIM requires specialized training and experience.

Best For:

This method is best for large, complex projects where accuracy and detail are critical. It’s particularly useful for commercial buildings, infrastructure, and projects with a high level of customization.

Area and Volume Take-Off

The area and volume take-off method is commonly used for projects that involve large quantities of bulk materials like concrete, soil, or paving. Rather than focusing on individual components, this method calculates the total area or volume of a material required.

How It Works:

- Measure the total surface area or volume that requires a specific material (e.g., concrete for a slab or asphalt for a road).

- Calculate the material quantity based on these dimensions (e.g., cubic meters for concrete, square meters for asphalt).

Pros:

- Simplified: Ideal for projects where the material requirements are based on bulk measurements.

- Fast: Calculating areas and volumes is quicker than breaking down every component.

Cons:

- Limited scope: Only suitable for materials that are measured in bulk, like concrete or soil.

- Less detailed: Does not account for smaller components like fixtures or fittings.

Best For:

This method is well-suited for infrastructure projects such as roads, bridges, or large-scale industrial builds, where bulk materials are the focus.

Subcontractor Take-Offs

In some cases, contractors will delegate the take-off process to subcontractors who specialize in specific areas, such as electrical, plumbing, or HVAC. Subcontractors perform their own take-offs based on the project’s drawings, providing the main contractor with material quantities and estimates for their trade.

How It Works:

- Subcontractors review the drawings and calculate the materials needed for their specific trade.

- Each subcontractor provides a take-off and estimate for their part of the project (e.g., electrical wiring, plumbing fixtures).

Pros:

- Expertise: Subcontractors have in-depth knowledge of their trade, leading to more accurate take-offs for specialized components.

- Reduces workload: The main contractor doesn’t have to perform take-offs for every aspect of the project.

Cons:

- Inconsistent formats: Different subcontractors may provide take-offs in different formats, making it difficult to consolidate.

- Coordination required: The main contractor must manage and coordinate multiple subcontractors.

Best For:

This method is ideal for large projects that require specialized trades, such as commercial buildings or multi-family housing developments.

Choosing the Right Quantity Take-Off Method

Each method of Quantity Take-Off has its own advantages and is suited for different types of projects. Whether you’re working on a small residential build or a large commercial development, selecting the right QTO method can make a significant difference in terms of accuracy, efficiency, and cost control.

- Manual QTO: Best for small projects or companies without access to digital tools.

- 2D Digital Take-Off: Ideal for medium to large projects with more complex drawings.

- 3D Model-Based Take-Off (BIM): Suited for large, detailed projects requiring precision.

- Area and Volume Take-Off: Perfect for infrastructure projects involving bulk materials.

- Subcontractor Take-Offs: Useful for large projects with specialized trades.

By mastering these methods, you’ll ensure your project stays on track, on budget, and on time.

Ready to Elevate Your Construction Projects?

Now that you’ve learned these 5 powerful methods to master quantity take-off, it’s time to put them into action! Whether you’re aiming for more accurate cost estimates or streamlined project management, these techniques can give you the edge.

Want to take your skills to the next level?

- Download our free guide for more in-depth strategies.

- Contact us today for personalized advice on improving your take-off process.

Don’t wait! Start optimizing your construction projects now for more precision, efficiency, and success.